Title: Unlocking Lithium’s Potential: Dynamic Flow-Through Lithium Extraction from Challenging Aqueous Environments with Engineered 3D-Shaped Layered Double Hydroxide Adsorbents

Duration: 2024-2028

Principal Investigator: Jakub Matusik (AGH University), Pegie Cool (University of Antwerp), Elena Mihaela Seftel (VITO NV Flemish Institute for Technological Research)

Funding agency: National Science Centre (Poland), FWO Research Foundation Flanders (Belgium)

Project ID: Opus 26/LAP

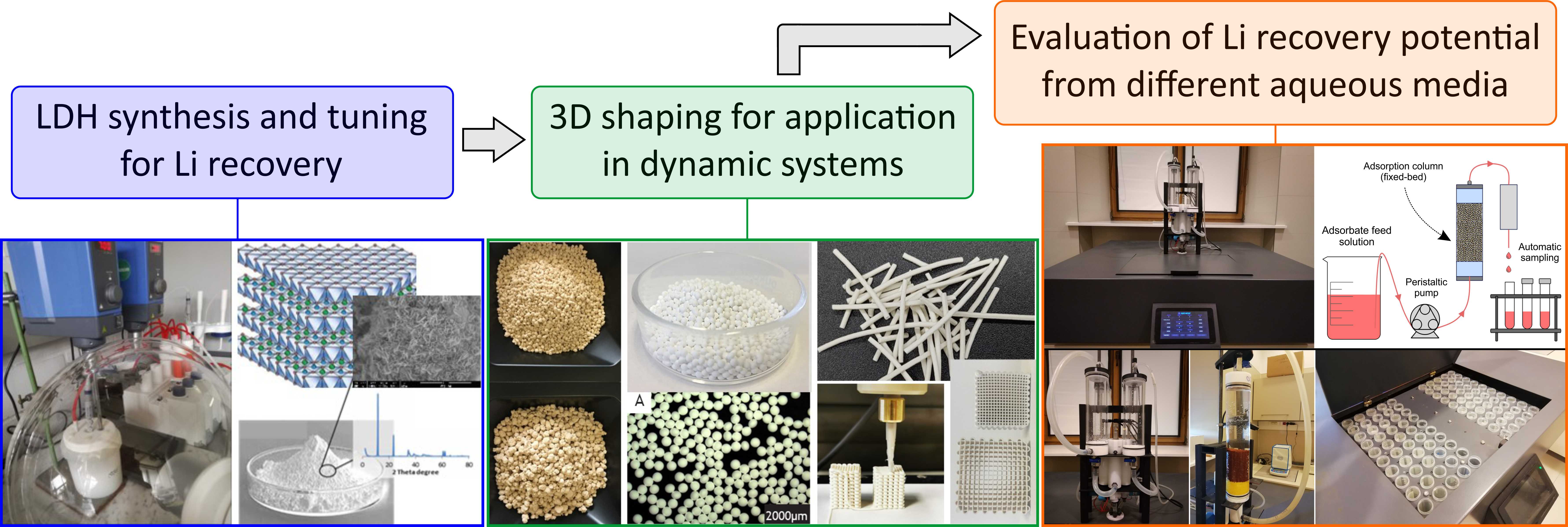

Lithium, renowned for its exceptional properties, has risen as a critical raw material especially in energy storage. Lithium is crucial for powering various technological advancements, as lithium-ion batteries have become the preferred choice for powering portable electronics, modern electric vehicles, and renewable energy storage systems. Traditionally, Li extraction was based mainly on mining methods, while nowadays the focus has been shifted to brine extraction via direct Li extraction (DLE), owing to its cost-effectiveness and environmental friendliness. DLE is expected to transform the Li sector, offering a sustainable path for meeting the global Li demand. DLE is a straightforward and efficient operational process, with broad applicability to various brine resources and significant economic benefits, but its efficiency is strongly dependent on Li-selective adsorbents. Particularly, the Al-based adsorbents including layered double hydroxides (LDHs) like LiAl-LDHs, are identified as the most favored for industrial Li extraction due to their technological maturity, low costs, ease of fabrication and regeneration under neutral media. Still, before their industrial implementation

further developments are needed to increase the adsorption capacity and most importantly the LDHs stability over multicycle use for prolonged operation. We aim to tackle these challenges by smart engineering at the atomic level (structure tuning) and at the macro level (3D shaping). We aim to achieve the best combination of Li adsorption features in terms of superior capacity, selectivity and long term stability. This will be done by engineering of the LDHs atomic structure via fine tuning of both layer and interlayer sites for precise anchoring of Li during DLE to prevent their deactivation.

Further, to enable their continuous dynamic operation, the engineered LiAl-LDHs powders will be 3D shaped as microspheres, fibers or monoliths, with tuned surface and internal porosity to overcome diffusion limitations and achieve an overall improved performance. Thus, a multiscale development approach is here proposed to obtain engineered 3D-shaped LiAl-LDH based adsorbents. At nanoscale level by fine-control of the synthesis conditions for controlling the LDH chemical composition, and continues to the meso- to millimeter scale levels through 3D shaping and demonstration of the materials’ efficiency for Li extraction in dynamic flow-through conditions.